- 3min

A clean thing: Gasoline & Diesel Engine System Cleaner

High fuel consumption?

Decreasing engine performance?

Engine not running smoothly?

Bad emission values?

Most effective with remedial use

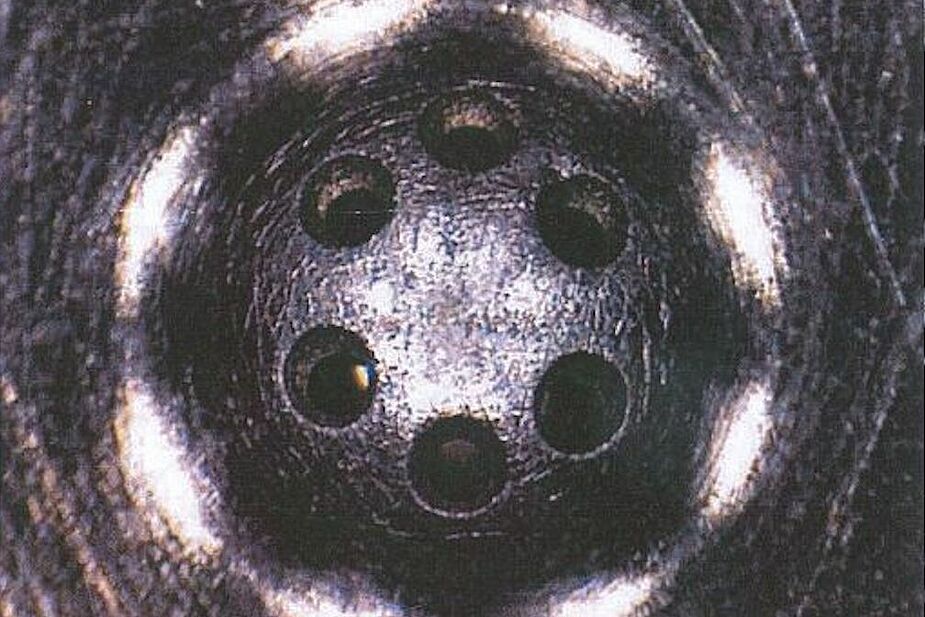

With every combustion process, components in the injection system are soiled. The more sophisticated the engine, the more sensitively the systems react to contamination and the more serious the problems that occur. With direct injection of fuel in particular the respective injection (gasoline or diesel) is installed in the combustion chamber. The consequence is that the sensitive nozzle head is permanently exposed to high temperatures, pressures and exhaust gases (including soot). Depending on the driving style and quality of fuel, deposits quickly form at the fuel outlets on the nozzle head.

Consequences

Soiled injection nozzles lead to losses of engine performance, which can be traced back to decreased fuel flow through the injection nozzle ducts. This leads to a loss of driveability and to an increase of emissions and fuel consumption. As time goes on, more combustion residues such as soot is produced, clogging the fine outlets even more. This results in even poorer combustion through to the injector being blocked or the system failing, entailing costly repairs.

Application

Can be added to the fuel at any time. Mixing takes place automatically. 300 ml sufficient for 35–75 l of fuel. Recommendation: Add to gasoline during inspection or other maintenance work on the fuel system. For preventative use after repairs to the fuel system, for treating problems or after every JetClean cleaning.

The Gasoline or Diesel Engine System Cleaner additive has the unique characteristic of almost completely removing DW10 injection valve deposits. To demonstrate this, a series of experiments were performed that demonstrate the potential of the engine system cleaner.

Gasoline injection system

The graphic illustrates the removal of deposits from the soiled injectors over an operating period of 24 hours with 450 mg/l of the additive.

Diesel injection system

The graphic illustrates the removal of deposits from the soiled injectors over an operating period of 16 test cycles with a consumption of about 400 l of fuel.