FAQ – Frequently Asked Questions

Here you will find answers to the most frequently asked questions about our products and general topics. Whether you need support or just want to learn more, our FAQs help you find the information you need quickly and easily.

If your question is not answered here, your contact will be happy to help you.

Page contents:

- Motor oils

- Additives

- Lubricants

- Vehicle problems

- Terms and definitions

Engine oils

No. You can of course always use the appropriate LIQUI MOLY product.

No. 2-stroke oil dissolves completely in fuel and does not segregate even after a long service life.

The color of an engine oil does not allow any conclusions to be drawn about its quality or age. For example, there are chemical additives that overlay the actual coloring (amber) of the oil and thus color it.

The decisive factors when selecting an oil are the quality and the manufacturer's approvals, not the viscosity. This information can be found on the container label. The specification 5W-30 only refers to the fluid condition of an oil at a certain temperature and is not a quality specification.

The miscibility of modern engine oils with each other, regardless of the type, must be ensured under all circumstances. This is because it is not always guaranteed that the average car driver knows which engine oil was used by the workshop when changing the oil.

Smaller quantities, such as when topping up the oil (approx. 1 liter), are therefore not a problem. However, we advise against mixing larger quantities of oil, as this may affect the effectiveness of the different engine oils.

Additives

Generally yes. However, LIQUI MOLY has a special motorcycle program in which this formulation is specially adapted to the smaller tank volumes of motorcycles.

When using conventional summer diesel fuels, which have a low-temperature resistance of 0 degrees Celsius, an improvement to -6 to -8 degrees Celsius is achieved with the correct dosage of Diesel Flow Fit.

We generally do not recommend it, but some combinations are possible. Please contact our application engineers regarding your specific request.

Yes, it is generally possible to mix a maximum of two different engine oil additives. However, the maximum total additive content of 10 percent in the engine oil should not be exceeded.

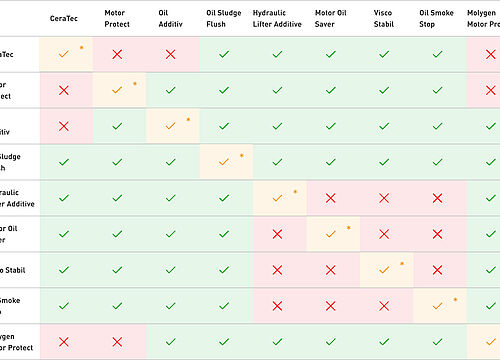

However, some additives cancel each other out. Please refer to our matrix to see which additives can be combined with each other.

We advise against this. The use of Oil-Loss Stop in engines with clutches running in engine oil can lead to clutch slipping due to the additives it contains.

Yes, because Oil-Loss Stop contains plasticizers and viscosity improvers. It regenerates elastomer seals and has a slightly viscosity-increasing effect at high temperatures. This results in more efficient lubrication of turbocharger bearings.

For clutches running in an oil bath, 20 ml of additive can be added per liter of engine oil. This prevents clutch slippage. For perfect dosing, we recommend the Motorbike Oil Additive or the Motorbike MoS2 Shooter.

However, we do not recommend the use of Motor Protect with clutches running in an oil bath.

Yes, this has been tested in a field test with company vehicles. The oil additive reduces wear by approx. 30 %.

Yes, our oil and fuel additives are formulated in such a way that they do not negatively affect each other or the overall mixture.

Yes, Motor Protect can be used in modern longlife oils such as Synthoil Longtime Plus 0W-30 and Synthoil Longtime 0W-30.

No, there is no improvement in low-temperature resistance with these fuels.

All information on the mixing ratios of individual products can be found on the product detail pages, on the product data sheets or on the label on the can.

Lubricants

Yes.

No! HLP oils are hydraulic oils and are not suitable for use in power steering systems. In the worst case scenario - especially at low temperatures - this can cause the steering system to fail. It is therefore essential to observe the manufacturer's approvals and requirements, as the steering is a safety-relevant component.

Gear oil loses power over time. Among other things, the viscosity and friction coefficients of the oil change, which has a negative effect on the transmission and shifting behavior.

This is caused by wear, abrasion, oil aging and condensation. In addition, in modern vehicles, higher temperatures in the engine compartment or due to encapsulated engines (to keep noise levels low) also have an effect. But the high torques of modern engines also make life difficult for transmissions.

You often read “lifetime filling”. For most manufacturers, however, “lifetime” only means a service life of 250,000 – 280,000 km. This service life can be greatly shortened by loads. The result is gearshift problems and high wear, in the worst case even failure of the transmission. Gearbox manufacturers such as ZF, on the other hand, recommend changing the gear oil every 80,000–120,000 km or after 8 years at the latest.

Vehicle Trouble

You can add Motorbike Speed Additive to the gasoline for optimum fuel combustion. In simple terms, the additive atomizes the fuel even more finely, so that it also burns faster. This improves the power delivery and acceleration characteristics of the engine. At the same time, Speed Additive cleans the injection nozzles.

Automatic transmissions require a special service and transmission fluid change. Even if automotive manufacturers talk about life-long durability for their automatic transmission fluids, transmission manufacturers say that the gear oil should be changed after 100,000 km at the latest.

Deposits in the transmission cause poor oil circulation, which can lead to shifting problems. Regular professional transmission service and timely gear oil changes are essential. Otherwise, the dirt and metallic abraded matter contained in the oil can cause expensive damage.

The problem can be solved by cleaning. The transmission fluid flush with transmission fluid change ensures that the transmission can withstand the loads in the long term. It then shifts like new.

The gears of your manual transmission are difficult to engage or a gear sticks? This can have several causes: a broken clutch or a worn clutch (recognizable by a cracking noise when changing gear). However, other defective parts can also cause shifting issues. Only repair at a service workshop will help with these problems.

However, there are certainly also harmless causes for shifting problems. Air in the clutch system could be a possibility. You can easily find out for yourself: Depress the clutch pedal a few times in succession. If the gears can then be shifted without problems, this indicates air in the hydraulic system.

Frequently, the transmission fluid level is often too low, or the gear oil is old or not suitable for your vehicle.

However, even if everything is correct, difficulties may still be encountered when shifting gears. Our special transmission fluid additive can help. It creates a highly stable lubricating film on the metal parts of the transmission, which reduces friction and solves many shifting problems. The gearshift is softened by the Gear-Oil Additive, the gears can be engaged better and the shifting comfort is significantly increased. The additive can also be used preventively so that shifting problems due to excessive friction do not occur in the first place. Your LIQUI MOLY service workshop can add the Gear-Oil Additive quickly and inexpensively for you.

In diesel vehicles, engine performance may be reduced even without a recognizable defect or reason. In extreme cases, the engine no longer starts or switches off.

A clogged diesel particulate filter may be the cause – if the indicator light for the filter lights up on the display, then you know for sure. Many short-distance trips make the problem worse, as the necessary self-cleaning temperature of around 600 degrees Celsius cannot be reached or kept constant for more than 30 minutes. In addition, the engine never warms up properly on short journeys, which leads to increased soot formation. The problem is therefore intensified.

There are several ways to clean the filter:

- Replacing the filter is always the most expensive approach and not always necessary.

- The most effective option is professional diesel particulate filter cleaning in a LIQUI MOLY partner workshop.

- The most cost-effective variant is the Diesel Particulate Filter Protector. The additive reduces the burn-off temperature of the soot particles in the diesel particulate filter, which means that the filter can be “blown free” even at lower temperatures and on short journeys.

Does the engine no longer respond and do you feel that the acceleration performance is decreasing? The cause of this is often quickly rectified and there is no defect or engine damage.

Many short distances and/or urban traffic quickly lead to carbon buildup in the injection system, which disrupts the ultra-fine atomization of the fuel when injecting into the combustion chamber. The fuel can no longer be ignited optimally and the efficiency of the engine decreases, fuel consumption increases, the engine runs more unevenly and acceleration is weaker.

Speed Tec Gasoline or Speed Tec Diesel can solve and prevent these problems. The additive removes deposits, ensures finer atomization of the fuel and thus more efficient combustion, which also improves acceleration.

Terms and definitions

The ACEA (European Automobile Manufacturers’ Association) has been the official successor to the CCMC since January 1, 1996. It defines the quality of the motor oils in accordance with the requirements of the European engine manufacturers.

An additive package is a mixture of various chemical substances that influence the properties of the motor oil in different ways.

The alkaline reserves of an oil neutralize acidic reaction products, which are created during the combustion of fuel.

An unwanted byproduct of circulation lubrication is the inclusion of small air bubbles in the motor oil. Anti-foam additives cause a significant reduction of foam created in the circulation of oil (air pockets).

The American Petroleum Institute (API) determines the global quality requirements and testing criteria for lubricants, such as motor oil and gear oil. Europe or European manufacturers are largely excluded from this.

So-called automatic transmission fluids (ATF) have a defined friction coefficient and a high viscosity index. The oils are mainly used in automatic transmissions and power steering.

Backwards compatible refers to a specification or release that meets and exceeds the previous (then obsolete) specification or release.

The base number shows the quantity of alkaline reserves in motor oils. In used oils, the base number gives an idea of the remaining additives that have not yet been used.

Base oil is the base product for the manufacture of lubricating oils. Base oils (mineral, hydrocracked or fully synthetic) are manufactured by various refinery processes.

In catalytic hydrocracking, the molecule chains are cleaved in the presence of a catalyst (e.g. synthetic aluminosilicates) and at a temperature of 500 °C.

In cracking, long hydrocarbon molecules are broken up. These broken molecule chains form the base product for synthetic oils.

Crude oil is a mixture mainly made up of hydrocarbons, which is created by the decomposition process of organic materials.

Detergents are wash-active substances in the oil, which prevent the formation of deposits or free the motor of them. Also, detergents form the so-called alkaline reserves.

During dewaxing, wax crystals are removed from the corresponding distillate, in order to improve the pour point (the lowest temperature in which the oil is still flowing when it is cooled under certain conditions).

The dispersants contained in motor oil coat solid and liquid contamination in the oil and transport them to the oil filter.

During distillation, crude oil is heated under atmospheric pressure and split into its constituents.

Extreme Pressure additives (EP) form a “protective layer” on the metal surfaces under high pressure and great heat.

Friction modifiers (FM) create weak bonds on the metal surfaces and thus reduce or increase the friction properties of a lubricant.

Fully synthetic base oils are oils based on polyalphaolefin. These are manufactured synthetically and offer high temperature and aging stability.

GL means Gear Lubricant and identifies the pressure stability of a gearbox oil according to API.

HTHS means High Temperature High Shear and refers to the dynamic viscosity of a liquid measured at 150 °C under the influence of high shear forces.

Hydrocracked base oils are manufactured on the basis of paraffin. These oils are currently state-of-the-art and are also used in cutting-edge gasoline/diesel engines.

During hydrocracking, long molecule chains are broken up in the presence of hydrogen. This hydrogen accumulates at the open chain ends and “repairs” the break.

Hydrofinishing refers to the addition of hydrogen to achieve optimum aging stability in the production of mineral base oil.

The International Lubricant Standardization and Approval Committee (ILSAC) develops performance standards for passenger car engine oils for gasoline engines. The API standards serve as the basis.

The Japanese Automotive Standards Organization (JASO) divides lubricating oils into various classes and is mainly used in the motorbike sector and in Asia.

Low-speed pre-ignition (LSPI) occurs predominantly in modern, low-volume turbocharged gasoline engines with direct injection. Particles or drops of oil heat up when the engine accelerates and form an additional ignition source which ignites the fuel before it is regularly ignited by the spark plug. This leads to “knocking” and up to threefold pressure spikes, which in turn can lead to engine damage.

Mineral base oils are a direct product of crude petroleum distillation. This type of base oil is no longer used in modern motors.

Naphta is petroleum, which represents a product of crude petroleum distillation.

The National Marine Manufacturers Association (NMMA) is the leading trade association in the United States representing boat, marine engine and accessory manufacturers and establishes oil certification programs for engines used in marine environments.

Wax crystals that form the byproduct of the manufacture of mineral base oil are described as paraffin or kerosene.

The pour point is the lowest temperature at which the oil will just flow when cooled under specified conditions.

A pour point depressant (PPD additive) changes the structure of the wax crystals in the base oil and delays their growth. This minimizes the solidification point of the oil or improves the low temperature property.

The pumping viscosity limit describes the test for classifying lubricants into the respective SAE classes. The viscosity of the corresponding SAE grade must not be exceeded at a specified temperature in order to ensure that the lubricant continues to flow automatically.

Refining is the removal/conversion of unwanted fractions from vacuum distillates.

SAE International (formerly the Society of Automotive Engineers) specifies the valid viscosity classes for motor and gearbox oils in the automotive industry, which manufacturers around the world conform to.

SAPS stands for sulfated ash, phosphorus and sulfur. These low- or mid-SAPS oils are mainly required in engines equipped with exhaust gas aftertreatment systems such as DPF or OPF.

Vacuum distillation further separates residues from distillation under reduced pressure. Through the vacuum, the boiling point can be reduced by approx. 150 °C and therefore the cracking of the molecules is prevented.

Viscosity is the resistance (inner friction) of a fluid. The higher the resistance, the more viscous the oil is. The viscosity in motor and gearbox oils is given according to SAE.

The viscosity index (VI) describes the viscosity/temperature behavior of the oil. The higher the VI, the lower the change in viscosity across the entire temperature range.

Viscosity index improvers are polymers that are designed to influence the temperature-dependent change in viscosity of an oil.