- 5min

Battle against engine wear: Our oil additives in comparison

The components of an engine are heavily stressed over many years by friction, heat and pressure. The surfaces of metallic components always have tiny irregularities or roughness. If they rub directly against each other, this can lead to wear and damage in the long term. In short: Parts such as pistons or cylinders wear out over time. This can and should be counteracted. Because attrition on the components can have a negative effect on the performance and service life of the engine. So it’s all about extra protection for the engine. And that’s exactly what our three oil additives can do against engine wear.

The question remains which of the three additives is suitable for whom and when.

Basic physical protection with Oil Additive

The classic among our additives. It was the first product we ever put on the market. Still available after 60 years, it now features an improved formula. It contains MoS2, the abbreviation for molybdenum sulfide.

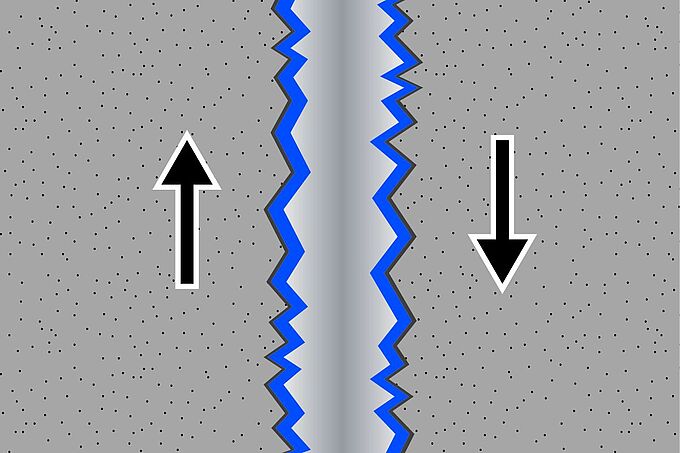

How Oil Additive works

The low-viscosity solid lubricant MoS2 it contains forms a highly resilient lubricating film on all rubbing and sliding metal surfaces. It reduces friction and ensures that the assemblies run more smoothly. This results in significant fuel and oil savings, scientifically proven wear reduction, high operational reliability, and emergency running properties.

Chemical protection with Motor Protect

Motor Protect is a modern additive that does without solid lubricants entirely. It is a chemical high-pressure wear protection additive.

- Motor Protect ensures optimum engine performance and smoother running.

- Other key benefits are a significant reduction in wear and prolonged engine service life.

- It is effective for at least 50,000 km.

How Motor Protect works

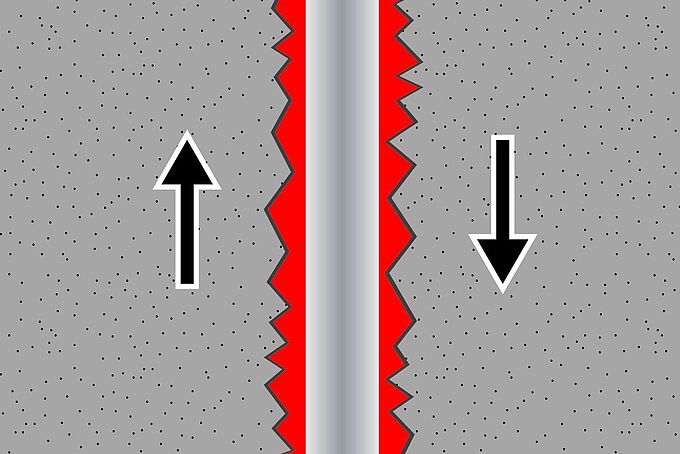

Motor Protect creates a very thin film on the engine’s sliding points that offers deformation and sliding capacity under wearing conditions.

The sliding points can be imagined as a mountain and valley landscape. When their tips meet, they weld together due to the temperature and pressures in the engine and then break away again. Motor Protect forms chemically reactive coatings. These reactive coatings have a very high load bearing capacity. They prevent so-called “fretting” and reduce attrition. Fretting would permanently damage the metal surfaces.

2-in-1: Physical and chemical protection with Cera Tec

Cera Tec is a high-tech additive for physical and chemical wear protection. It therefore combines the advantages of Oil Additive and Motor Protect.

- Unlike Oil Additive, Cera Tec doesn’t use MoS2 as a solid lubricant but tiny ceramic particles instead.

- The chemically and thermally highly stable microceramic ingredient creates a smooth running effect.

- The effects of Cera Tec protect the engine for up to 50,000 kilometers.

How Cera Tec works

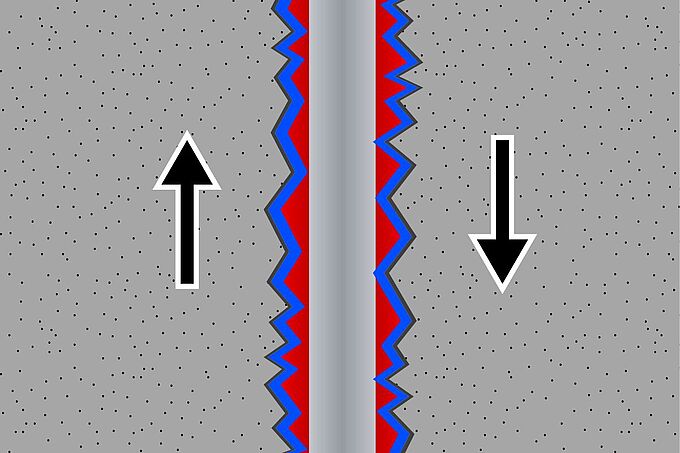

The active chemical agent in Cera Tec smooths the surfaces.

In addition, ceramic particles fill in the small unevenness in the metal and thus prevent the metal surfaces from rubbing directly against each other.

The graphic shows how Cera Tec combines the two principles of action of Motor Protect and Oil Additive: a microceramic solid lubricant and chemical reaction ensure optimum protection from wear and tear.